Forklift Operator Training

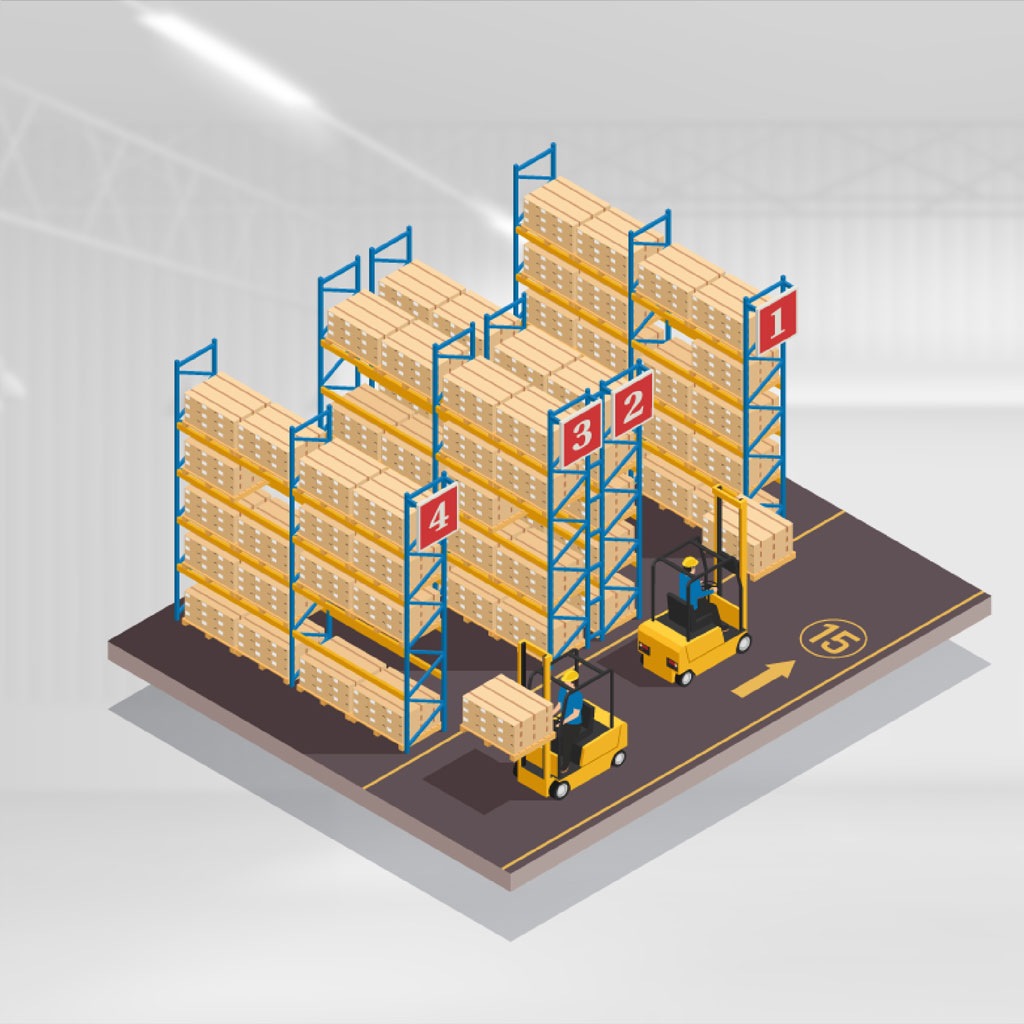

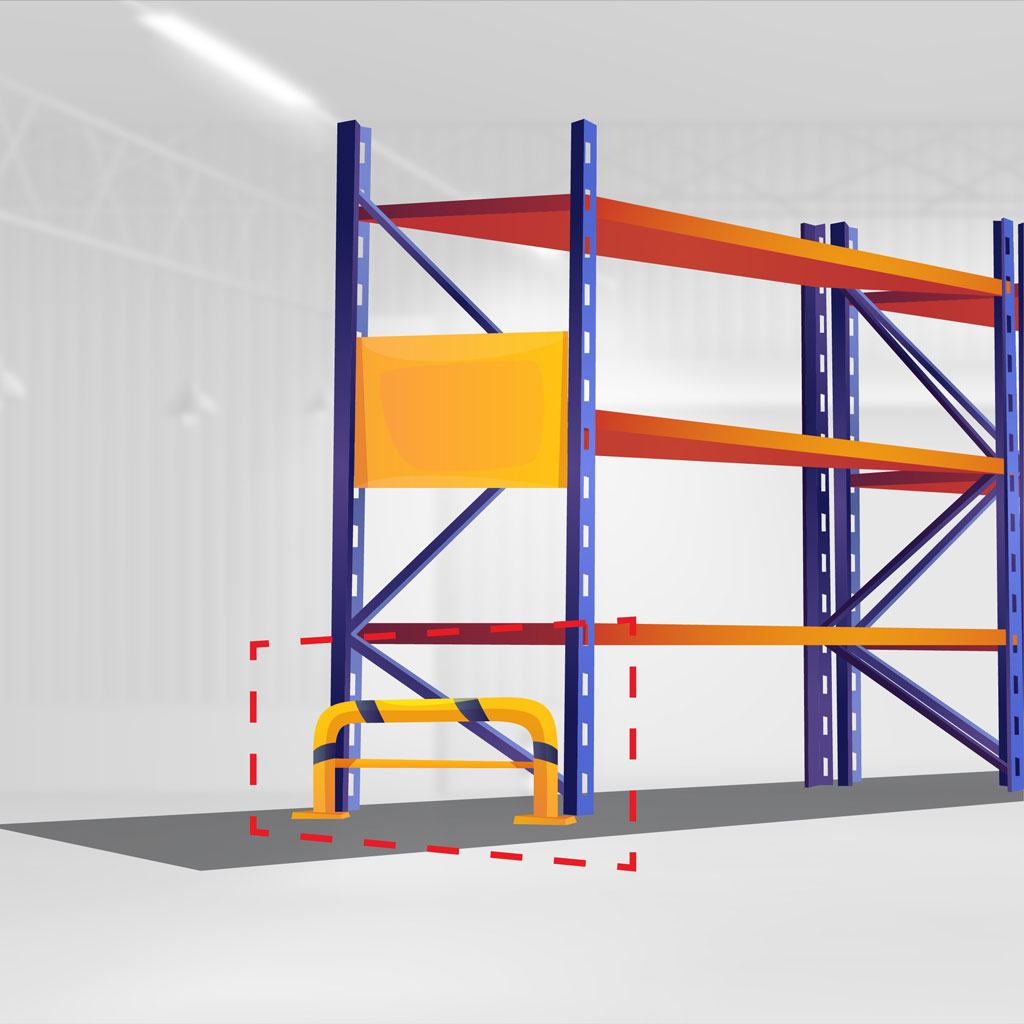

Pallet rack failures resulting in damage can be attributed to various factors, but one frequently encountered issue is the presence of untrained forklift operators. Operating heavy machinery can pose challenges, often requiring navigating tight turns and presenting a risk of unintentional collisions with adjacent racks.

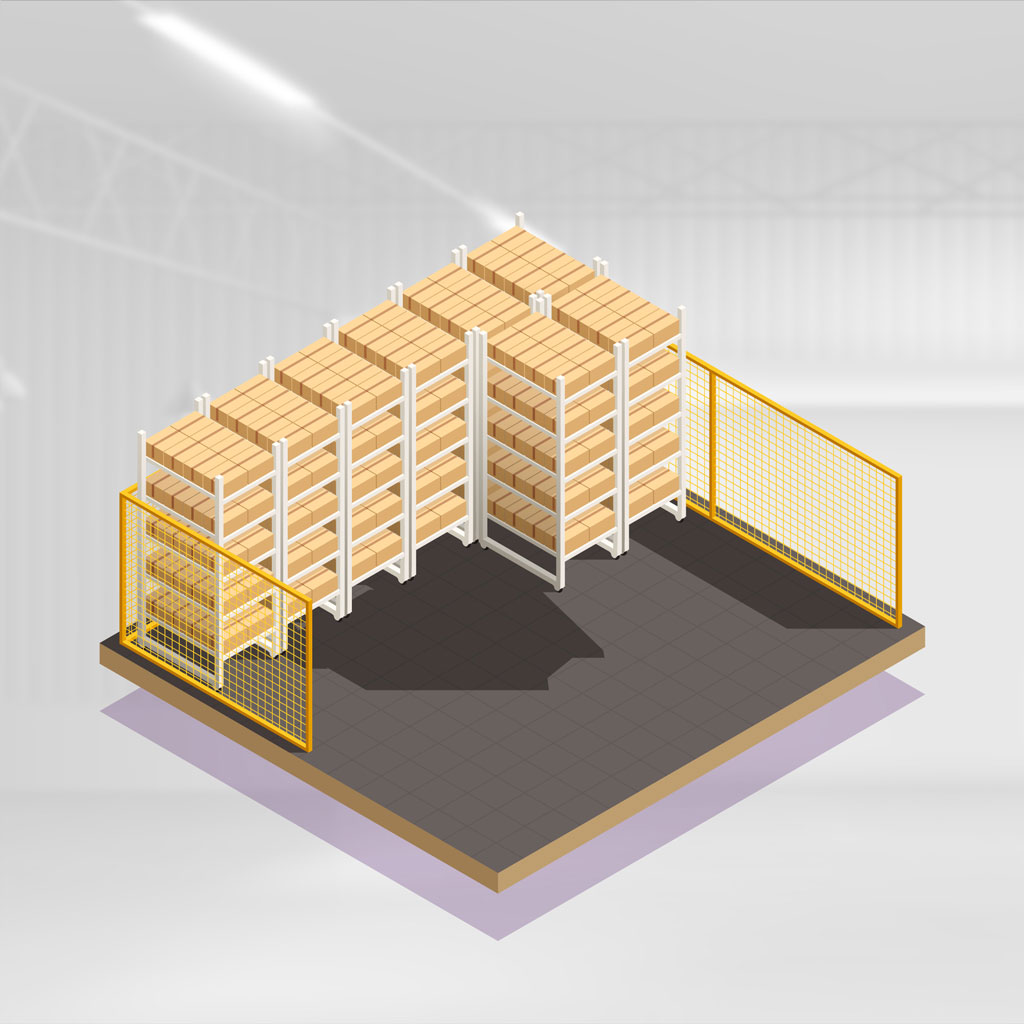

To ensure warehouse safety and prevent accidents, it's imperative to adhere to OSHD regulations, which mandate comprehensive training for all forklift operators. This training is a crucial step in maintaining a secure and incident-free warehouse environment.